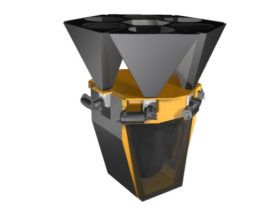

Gravimetric batch systems GRAVI are sum-of-weight equipments employed to realize homogeneous mixtures of several components.

They are available in several configurations to achieve outputs from 20 to 1200 kg/h. Depending on the type of material to be dosed and the dosage percentage of each component, they can be supplied with dosage valves or with single screw dosage units.

They have been designed to provide precise and reliable dosage. The predisposition to a quick disassembly allows easy and fast cleaning.

Dosing screws are inclined for accurate material feed.

The mixer is spherical to avoid material stagnation and for certain types of applications (for instance film extrusion), it is positioned on load cells to calculate the output of the extruder.

Indicated outputs are based on tests with material in granule having BD 0,60 kg/dmc

Application

The dosage and mixing systems GRAVI can be installed directly on the extruder instead of its feeding hopper or on the ground to feed several extruders.

Main sectors of use:

– extrusion

– injection moulding

– blow moulding

– recycling

Operation

Gravimetric batch systems GRAVI are sum-of-weight (or batch) equipments where all the materials are weighed into one scale in a sequential manner. The sum of all components (or batch) is then discharged into a mixer.

Advantages

– precision and repeatability of the performance in time

– monitoring of production costs (total consumption)

– control of the output of the extruder

– absence of periodic sampling operations

– supervision of the dosing process