Plasco’s technicians, thanks to their decades of experience, can claim a specialization in the design of complex centralized dosage and conveying systems, developed according to the specific requirements of each customer.

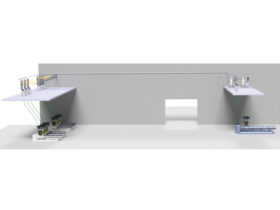

These systems are mainly used in extrusion and can operate different lines simultaneously. The system manages every step of the extruder feeding process, from the transport of raw materials to the recipe to be conveyed to the extruder and for this reason it is very important that it is designed in detail and that it’s managed by the best available technology on the market to be able to guarantee to the customer reliability and accuracy.

Application

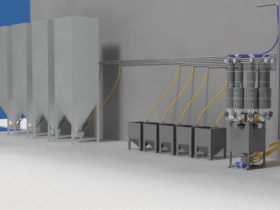

The dosing station and preparation of the recipe is placed on the ground. For each extruder there will be a mixer that, depending on the type of application, can be placed on the ground or directly on the extruder.

Main sectors of use:

– extrusion

– injection moulding

– blow moulding

Operation

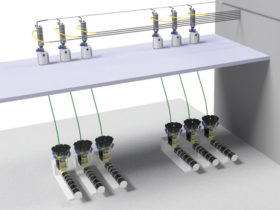

The dosage of each single material is effected by means of valves or dosage units, on the basis of the specific characteristics and of the percentage of use. The components are dosed individually into a weighing tank supported by load cell; at the end of the weighing cycle the batch is discharged into a conveyor.

Each recipe is transported pneumatically to the extrusion line to which it is associated by means of a sophisticated aspiration cycle which guarantees full transfer without the danger of pollution with the previous recipe or the next one.

The entire operation cycle, including weighing of components, is completely controlled by a high precision and highly reliable PLC. The operator panel is easily programmed using a functional keyboard and a touch screen display. The operator simply inputs the dosage percentages of each component and associates the recipe to the relevant destination line. The system will automatically and safely manage the formation and the transfer of the recipe.

Advantages

– single withdrawal point for the different components

– single station on the ground to prepare the recipes

– simplicity, efficiency and precision in the dosage

– feeding of each extrusion line through a single pipe

– Improvement of the quality of the final product

– saving on labour costs

– single operator panel to manger the entire system